Bike frame material has a huge impact on how a bicycle rides. The four main frame materials today are steel, aluminum, carbon fiber, and titanium, each coming with its own set of strengths and weaknesses – there’s no single “best” material for every rider. Understanding the differences will help you choose a frame that fits your riding style and priorities.

Steel Frames

Steel is the oldest and one of the most common bike-frame materials. Classic steel bikes have a loyal following because of their durability and smooth ride feel. Modern steel frames are usually made from chromoly steel (an alloy of steel with chromium and molybdenum) rather than plain high-tensile steel. Chromoly is lighter and stronger than basic high-tensile steel, allowing manufacturers to use thinner tubes and save weight while maintaining high strength.

Pros of Steel Frames

- Exceptional Durability: Steel has ultimate tensile strength and can last for decades of hard use. It’s highly resistant to fatigue (repeated stress), meaning a well-made steel frame can handle years of rough roads or trails without cracking.

- Comfortable Ride: Steel has a natural springiness that absorbs bumps and vibrations from the road. This compliance gives steel bikes a famously smooth, “planted” ride quality. Riders often describe steel’s ride as lively or forgiving – great for reducing fatigue on long rides.

- Predictable Handling: Most steel frames use relatively slim tubes, which can make for balanced, stable handling. The material’s toughness also suits bikes designed to carry heavy loads (like touring or bikepacking rigs).

- Ease of Modification and Maintenance: Steel frames are friendly to work with. Framebuilders can easily cut, weld, or add braze-on mounts to steel. Small dents can often be bent back or even ignored if they’re not critical.

- Environmentally Friendly: Steel frames can have higher resistance to cracking and overall damage. If a steel frame is damaged, fixing it is a suitable option unlike with other materials, such as carbon fiber.

Cons of Steel Frames

- Heavier Weight: Steel is dense and by volume weighs more than aluminum, titanium, or carbon. Even with thin-wall chromoly tubing, a steel frame is usually the heaviest option for a given bike design. This extra weight may not matter for casual riding, but it can be a disadvantage in racing or fast climbing where every gram counts.

- Can Rust: Steel’s biggest maintenance concern is corrosion. If the paint is chipped and bare steel is exposed to moisture, it will oxidize (rust) over time. In wet or humid climates, a steel frame needs a bit more care – you’ll want to keep it clean and touched up with paint to prevent rust.

- Flex (Lower Stiffness): Steel frames tend to be less stiff than other materials, meaning the frame can flex under heavy pedaling load. That flex is what gives steel its comfort, but it also means you lose a bit of efficiency during all-out sprints or climbs.

- Availability and Cost Range: While basic steel bikes (like many city bikes or entry-level mountain bikes) are quite affordable, high-end steel frames built with premium alloys can get expensive. Good steel requires skilled craftsmanship and isn’t as mass-produced as aluminum. As a result, mid-range and high-end steel frames are often made by smaller boutique brands.

Build Your Ride on Steel

At Thomson Bikes, our steel frames are designed with the same precision and attention to detail that define our legendary components.

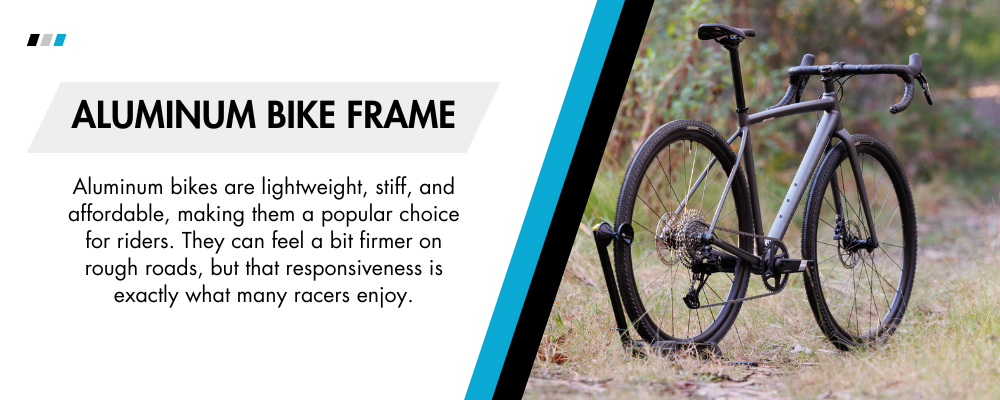

Aluminum Frames

Aluminum (or “alloy”) frames have become the most common choice for modern bikes. Aluminum’s popularity comes from its light weight, decent strength, and ease of production. Most “alloy” bikes you see are made of aluminum alloys (often 6061 or 7005 series aluminum, which include small amounts of other metals for strength). Unlike steel, aluminum is not used in pure form for bikes – it’s always alloyed to improve its strength-to-weight ratio.

Pros of Aluminum Frames

- Lightweight: Aluminum is much lighter than steel. This allows bike makers to build frames that weigh significantly less, which helps you climb hills and accelerate with less effort.

- Stiff and Efficient: Aluminum has a high stiffness-to-weight ratio. Tubes can be made larger in diameter to increase frame stiffness without adding much weight (because the material is light). The result is a very responsive ride – when you pedal hard, an aluminum frame doesn’t flex much, so most of your energy goes into forward motion.

- Corrosion Resistance: Unlike steel, aluminum won’t rust. The metal naturally forms a thin oxide layer that protects it from moisture. This makes aluminum frames low-maintenance in terms of weather.

- Affordable: Aluminum frames are relatively easy and cost-effective to manufacture. The material is abundant and melts at a lower temperature, and manufacturers have decades of experience with aluminum welding techniques. As a result, aluminum bikes usually cost less than carbon or titanium bikes with similar components.

- Versatility in Design: Modern aluminum frames use techniques like hydroforming (shaping tubes using high-pressure fluid) and butting (varying wall thickness) to fine-tune performance. Engineers can shape aluminum tubes in ways that aren’t possible with steel.

Cons of Aluminum Frames

- Harsher Ride Quality: The flip side of aluminum’s stiffness is a harsh ride on rough terrain. Aluminum doesn’t absorb vibrations as well as steel, titanium, or tuned carbon fiber. There’s less natural flex, so bumps and road “buzz” get transmitted to the rider more directly. If comfort is a top priority, aluminum might not be ideal without some added cushioning (like wider tires).

- Finite Fatigue Life: An aluminum frame can handle hard riding, but the material fatigues over time. Every material has a fatigue limit; steel and titanium have higher thresholds, whereas aluminum accumulates microscopic cracks with repeated stress until eventually, it can fail.

- Not Easily Repairable: If an aluminum frame does crack or get bent, it’s difficult to repair. Aluminum requires specialized welding techniques and heat treatment after welding to restore strength. A cracked aluminum head tube or bottom bracket weld is usually the end of the frame – bike shops generally don’t fix these, whereas a steel frame crack could be re-welded by a professional.

- Can Feel Too Stiff: While racers enjoy stiffness, some riders find that aluminum’s lack of flex makes the bike feel a bit “skittish” or unforgiving in certain situations.

- Mid-Range Lifespan: An aluminum frame is often considered a great “middle-ground” option – lighter than steel, cheaper than carbon – but it might not be a frame you keep forever. Many riders start with an aluminum bike and later upgrade.

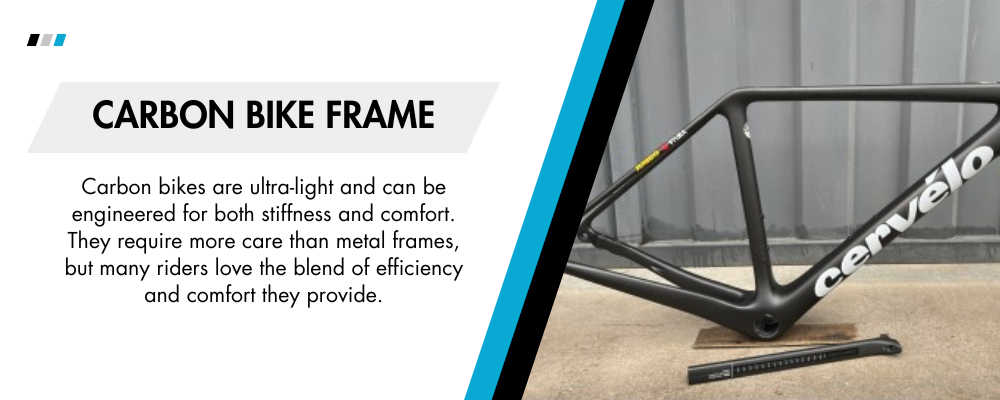

Carbon Fiber Frames

Carbon fiber is the material of choice for high-performance bicycles. Unlike steel, aluminum, and titanium – which are metals – carbon fiber is a composite material. It consists of extremely thin strands of carbon that are woven into sheets and bonded with epoxy resin. Bike builders layer these sheets in different orientations and cure them in molds to form the bicycle frame structure. The big advantage of carbon is that engineers can tune its properties by design, creating frames that are incredibly light, stiff in some areas, and compliant in others. Almost all pro racers now ride carbon frames, but carbon is also common in road and mountain bikes at many price points.

Pros of Carbon Fiber Frames

- Ultra Light Weight with High Stiffness: Carbon fiber has the best strength-to-weight ratio of any common bike frame material. At a given stiffness level, a carbon frame can be made significantly lighter than an aluminum, steel, or titanium frame. This is why virtually every Tour de France-winning bike for the past two decades has been carbon.

- Tunable Ride Quality (Stiff and Compliant): Carbon’s trick is that frame designers can lay up the fibers in specific directions to dial in where the frame is stiff and where it can flex. This targeted stiffness/compliance is much harder to achieve with metal frames. The result is a bike that can be very stiff where you need it, yet still cushions vibrations and chatter for comfort.

- Aerodynamic and Creative Shapes: Because carbon sheets can be molded into almost any shape, designers have enormous freedom in frame geometry. This ability to sculpt the material means carbon bikes can be made very aero without adding much weight. It also allows unique frame aesthetics – sleek designs with no visible welds, which many riders find visually appealing.

- No Corrosion Issues: Carbon fibre frames are impervious to rust or corrosion. You don’t have to worry about road salt, moisture, or sweat causing any degradation of the material. This makes carbon a low-maintenance choice in terms of weather durability.

- Widely Used at All Levels: While carbon was once exotic and expensive, it’s now very common. Many major brands offer carbon models in their lineup from elite racing bikes down to more affordable enthusiast bikes.

Cons of Carbon Fiber Bike Frames

- High Cost: Carbon frames tend to be more expensive than metal frames. While prices have come down, you’ll generally pay a premium for a carbon bike compared to an aluminum one with similar components.

- Brittleness and Damage Sensitivity: Carbon fiber is strong under normal loads but relatively brittle on sharp impacts. Unlike metal, which can bend and dent, carbon tends to crack or fracture when overstressed.

- Difficult Repairs (Specialized): Repairing a broken or cracked carbon frame usually involves a carbon fiber specialist who can re-lay new carbon fibers and epoxy over the damaged area, then re-finish it. This process can be costly, and not every bike shop can do it.

- Variation in Quality: The performance of carbon frames can vary widely. One carbon bike might feel harsh and heavy, while another feels responsive and smooth. When shopping, it’s important to stick with reputable brands or ones that clearly explain their carbon technology.

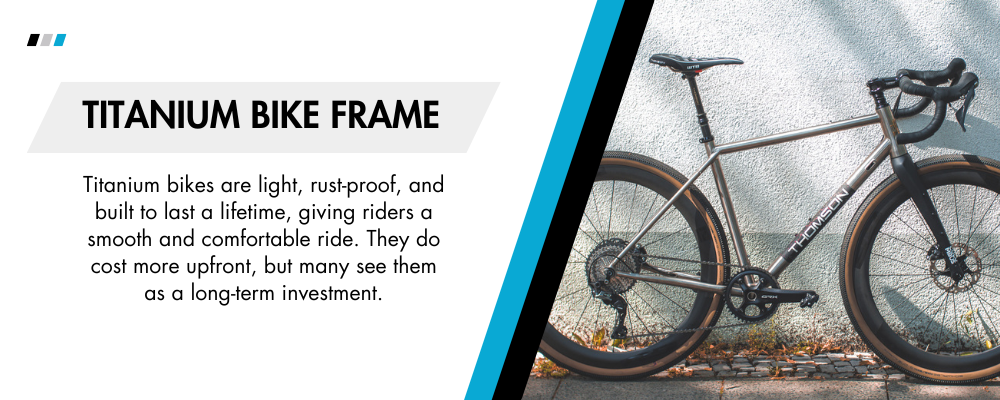

Titanium Frames

Titanium (often“Ti” in cycling) is sometimes considered the dream frame material for dedicated bike enthusiasts. It’s not as common as the other materials due to its cost, but a well-made titanium frame combines many of the best characteristics of steel and aluminum – light weight, strength, a superb ride quality – along with corrosion-proof durability. Titanium is a metal, but it’s less dense than steel and more flexible than aluminum. Most Ti bike frames use titanium alloys like 3Al-2.5V (meaning 3% aluminum, 2.5% vanadium, and the rest titanium) which improve strength and workability.

Pros of Titanium Frames

- Light and Strong: Titanium has the highest strength-to-weight ratio of any metal commonly used in bikes. In practical terms, you can build a titanium frame that is as light as an aluminum frame, yet as strong (or stronger) than steel.

- Excellent Ride Quality: Like steel, Ti has a bit of flex and vibration absorption, which helps soak up bumps and chatter from the road. This makes titanium popular for endurance road bikes, gravel bikes, and hardtail mountain bikes where comfort over long distances is valued. You get a nice amount of compliance without the weight penalty of steel.

- No Rust, No Corrosion: Titanium is completely immune to rust or corrosion. It doesn’t need paint or any surface treatment to resist the elements. This is a huge plus for low maintenance.

- Long-Term Durability: A titanium frame is extremely durable and fatigue-resistant. Ti has a bit of “give,” which means it can flex under stress and return to shape without developing cracks. It’s highly resistant to metal fatigue. Many riders describe titanium frames as nearly indestructible under normal riding – it’s not unusual to hear of Ti bikes still going strong after 20+ years.

- Balanced Performance: Titanium offers a very balanced ride performance. It’s not quite as stiff as carbon or some aluminum frames, but it’s stiffer and more responsive than many steel frames of equal weight.

- Aesthetics and Feel: Many people love the look of raw titanium. That gunmetal grey shine and the knowledge that it’s an exotic aerospace material adds to the allure. Ti also doesn’t require flashy paint – its timeless, rugged look is part of the branding.

Cons of Titanium Frames

- High Cost: Titanium is an expensive material and very labor-intensive to work with. The raw titanium tubes themselves cost much more than steel or aluminum tubing. Ti also requires meticulous welding in an oxygen-free environment because the metal is sensitive to contamination when hot.

- Limited Availability: Because of the cost and niche demand, titanium frames are less common in bike shops. You typically won’t find a cheap Ti bike. They’re mostly offered by boutique manufacturers or as custom builds. This means fewer model choices and sometimes longer wait times.

- Not the Absolute Stiffest: While titanium is reasonably stiff, it’s true that an uber-light Ti frame won’t be as rock-solid in a full sprint as the stiffest carbon racing frame or even a stout aluminum frame. The material’s stiffness is lower, so to reach the same rigidity, builders may use larger diameter tubes or thicker walls.

- Difficult to Repair (But Rarely Needed): If you somehow do damage a Ti frame significantly, repair options are limited to specialty framebuilders. The good news is that such damage is rare. Ti doesn’t crack easily unless under extreme stress.

Ride Titanium for a Lifetime

Thomson titanium frames are corrosion-proof, lightweight, and built to deliver decades of reliable performance.

Choosing the Right Frame Material for Your Needs

| Riding Style | Best-Suited Materials | Why They Work |

|---|---|---|

| Road Racing & Performance | Carbon, Aluminum | Carbon is light and stiff, making it the pro racing standard. Aluminum is a strong alternative for racers on a budget who still want fast handling. |

| Mountain Biking (Trail/Enduro/DH) | Aluminum, Carbon (Steel/Ti for hardtails) | Aluminum is durable and affordable, handling crashes well. Carbon is lighter and tunable for compliance. Steel and Ti hardtails appeal to riders who want comfort and long-term durability. |

| Gravel & All-Road | Carbon, Aluminum, Steel, Titanium | Carbon and aluminum deliver a racier feel, while steel and Ti are preferred for long-distance comfort and rugged reliability. Bikepackers often lean toward steel/Ti; racers toward carbon. |

| Touring & Bikepacking | Steel, Titanium (Aluminum for light setups) | Steel is time-tested for loaded touring, tough and repairable anywhere. Titanium offers the same resilience with less weight and no rust. Aluminum can suit lighter bikepacking; carbon is rarely used. |

| Commuting & Urban | Steel, Aluminum | Steel provides toughness and a smooth ride. Aluminum is lighter, rust-resistant, and practical for daily city use. Carbon and Ti are unnecessary here. |

Thomson Titanium and Steel Frames

Thomson Bikes has earned the trust of cyclists worldwide by focusing on what matters most: precision, performance, and reliability. Our titanium and steel frames continue that tradition, giving riders the choice between two legendary materials.

We don’t just build bikes, we build them to last. From frames to complete builds, every Thomson bike reflects decades of expertise in creating parts that riders depend on in the toughest conditions.